Seal Identification

Here are a few ways we can help you identify which type of seal you have:

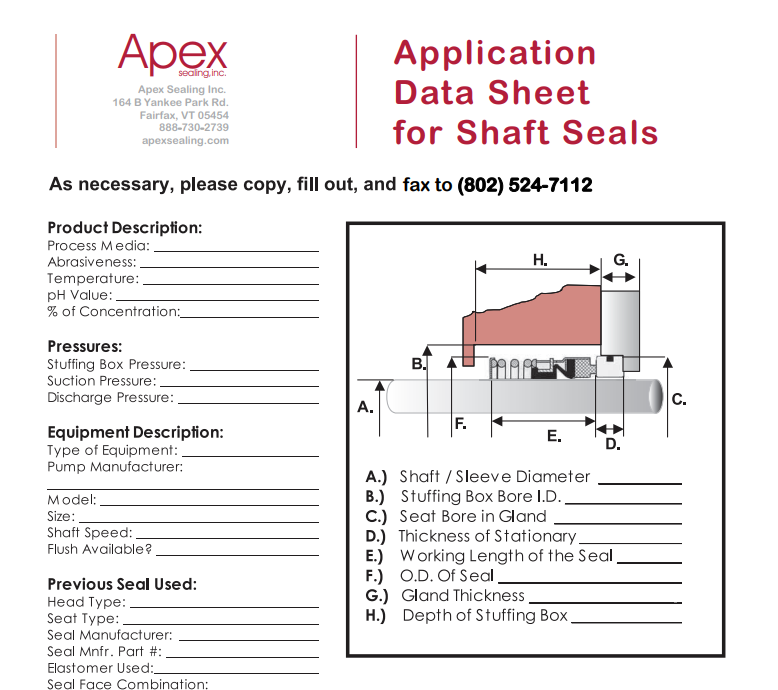

Application Data Sheet for Shaft Seals

1. The Shaft Seal Data Sheet

- Fill out and fax over our shaft seal data sheet.

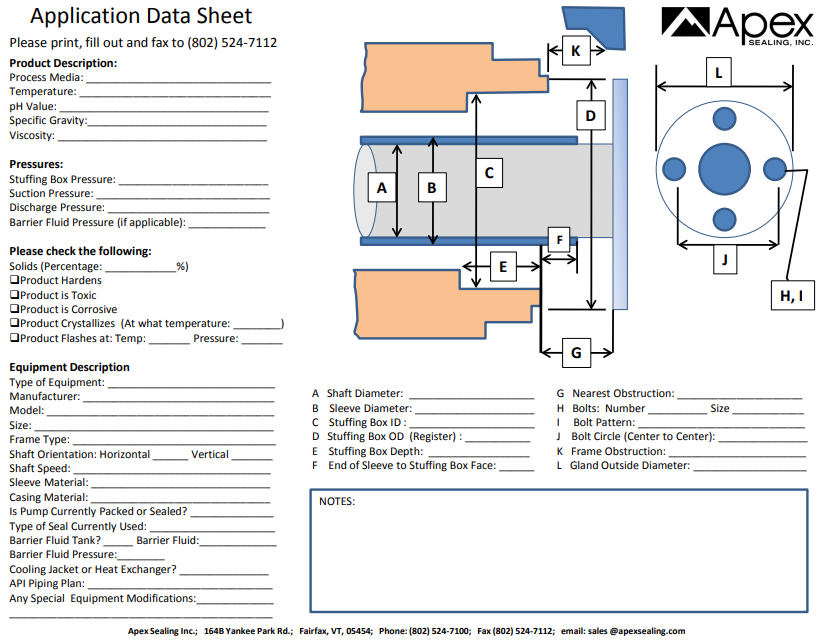

Application Data Sheet

2. Comprehensive Data Sheet

- Fill out and fax over our comprehensive data sheet.

3. Send it in

- Simply pack up your seal and mail it to our shop at :

164 B Yankee Park Rd

Fairfax, VT 05454

4. Email us pictures of the seal

- Simply email us photo's of the entire seal; top bottom and sides.

5. Comprehensive seal autopsy

- Root cause of failure

6. Common Rubber Bellows Shaft Seal Identification

- The key to identifying these seals is how the head sits upon the spring.

- Each will have unique head OD's.

- Each will have different operating lengths.

- To determine the correct Rubber Bellows Shaft Seal - Read more below:

Seal Identification

Rubber Bellows Shaft Seal Identification

The key to identifying these seals is how the head sits upon the spring.

- Each will have unique head OD's.

- Each will have different operating lengths.

To Determine the Correct Rubber Bellows Shaft Seal:

- Identify the type

- Determine the shaft size

- Measure the inside diameter of the Rubber Bellow. The dimensions will typically be slightly under the actual shaft diameter. This is what gives the Bellows the grip on the shaft.

- Measure the outside diameter of the rotary head.

- Estimate the operating length.

The best way to determine the operating height of a seal, if not given to you by the customer, is to obtain the axial dimension in the pump from the stationary face back to the point where the seal "stops" against.

If that is not possible, the approximate operating length can be found by adding:

- 1/2 of the spring's free length

- The distance from the point of the rotary head where the spring makes contact out of the top of the seal face

*Note that this is a rough estimate of the working length. Please refer to the catalog for the actual operating length.

Determine the Stationary:

- Determine the type of stationary (cup mount, O-ring groove, block, etc.).

- Measure outside diameter. This will be slightly larger than the actual gland bore, giving the seat the proper "squeeze" into the bore.

- Measure thickness of the seat.

Determine the Materials of Construction of the Seal:

- Type of metal spring and component parts

- Rotary face material

- Type of rubber elastomer and cup/O-ring

Determining the Correct Rubber Bellows Shaft Seal:

Translate your measurements and seal identification information to the actual seal part number.

Most people use the U.S. Seal catalog to determine the industry standard part number.